For manufacturers of tyres, conveyor belts, hoses, molded seals and countless rubber goods, product life isn’t just a technical benchmark — it’s the heart of your brand reputation. A tyre that cracks early, a conveyor that fails under load, or a seal that becomes brittle costs far more than just replacement. It leads to downtime, warranty claims, and frustrated customers who may never return.

Yet too many factories overlook two of the most critical (and cost-effective) factors driving long-term rubber performance:

✅ Zinc oxide — which supports crosslinking and protects against aging.

✅ Antioxidants — which fight ozone, heat, and oxygen degradation.

Getting these right can easily add months or years to your product life. Getting them wrong risks costly rejections or field failures.

🔍 The hidden roles of zinc oxide & antioxidants

Most buyers think of zinc oxide (ZnO) only as an activator in vulcanization — helping accelerators like CBS, MBT, MBTS or TMTD form the sulfur crosslinks.

But high-quality zinc oxide does far more:

| Function | Why it matters |

|---|---|

| Activates curing | Ensures complete, uniform vulcanization |

| Enhances heat aging resistance | Slows cracking under repeated flex & heat |

| Supports adhesion | Crucial in multi-ply tyres & belts |

| Helps dispersion of accelerators | Gives consistent cure throughout batch |

Similarly, antioxidants like 6PPD, IPPD, or other amine & phenolic blends protect your rubber from:

- Ozone & UV cracking (fine surface cracks that grow over time)

- Thermal oxidation (rubber hardens, loses elasticity)

- Flex fatigue (small internal cracks that lead to catastrophic failures)

⚠ Common problems caused by poor levels or wrong grades

Many plants — especially new startups — focus on lowering chemical cost per kg. Unfortunately, cutting back on zinc oxide purity or antioxidant loading is a classic false economy.

Here’s what we see in the field:

| Symptom in final product | Likely issue with ZnO / Antioxidants |

|---|---|

| Early surface cracks on tyres or belts | Not enough antioxidants / wrong type for ozone & flex |

| Under-cured spots (soft areas) | ZnO purity too low or poor dispersion |

| Adhesion failures (plies separating) | Low ZnO or excessive ash in ZnO blocking bonds |

| Loss of elasticity after few months | Insufficient antioxidant protection against heat |

In many cases, replacing these products in the field costs 10-20x more than using slightly better formulations upfront.

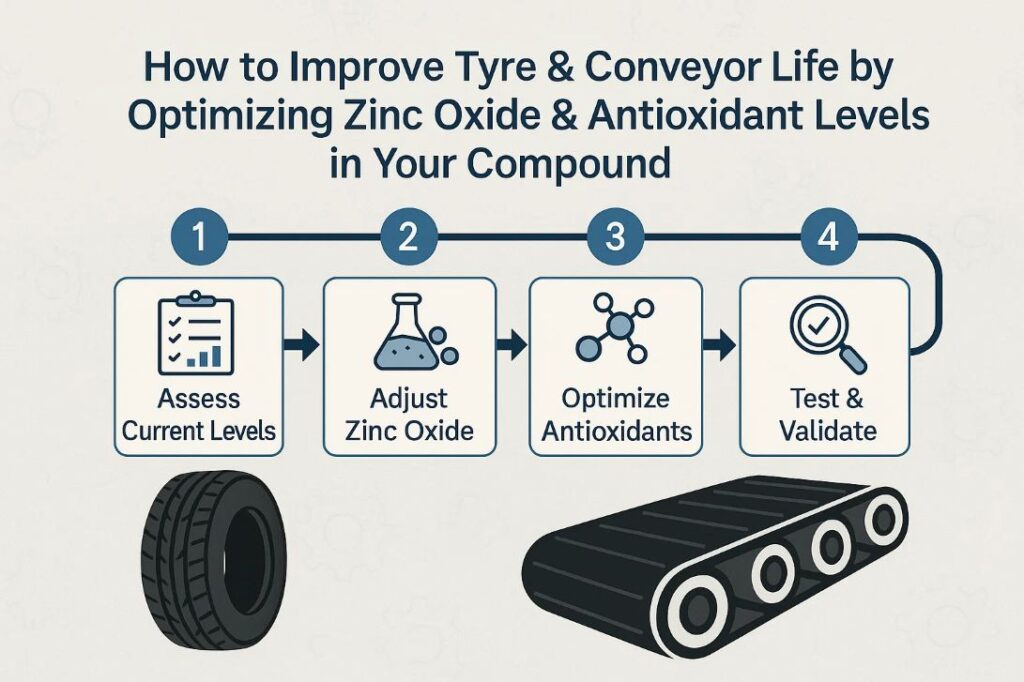

📝 How to optimize your zinc oxide levels

So how do you make sure you’re not undercutting your own tyre, conveyor or molded part lifespan?

✅ Use the right zinc oxide grade.

For most tyre & belt compounds, a 99%+ purity ZnO with low lead (Pb < 50 ppm) and SSA around 4-6 m²/g is ideal.

Higher surface area gives better activity but can raise viscosity; balance this with your compound needs.

✅ Typical ZnO levels:

| Application | ZnO Loading (phr) |

|---|---|

| Tyre treads & sidewalls | 3.5 – 5.0 |

| Conveyor belts & heavy duty parts | 4.0 – 6.0 |

| Molded seals, hoses | 3.0 – 4.5 |

Talk to your compounders and always test on your own equipment — under- or over-loading can impact cure kinetics and physicals.

🛡 How to dial in your antioxidants

Antioxidants aren’t one-size-fits-all. 6PPD and IPPD are popular amine types because they protect well against both ozone cracking & heat aging. Phenolic types (like SP or non-staining systems) might be better for light-colored or specialty compounds.

✅ Common antioxidant ranges:

| Compound Type | Typical Antioxidants (phr) |

|---|---|

| Tyres & heavy-duty belts | 1.5 – 2.5 (amine + phenolic blends) |

| General molded rubber | 1.0 – 2.0 |

| Light / color-sensitive | Use non-staining phenolics |

Also watch synergy with waxes — for outdoor or exposed parts, combining wax + antioxidant helps form a protective micro-layer.

🔬 A note on testing & batch consistency

Always work with suppliers who provide:

- Detailed COAs (Certificate of Analysis) for each batch, including ZnO purity, SSA, heavy metals.

- Batch-to-batch consistency reports, especially for antioxidants like 6PPD where amine content impacts performance.

- Technical support for rebalancing recipes if you change accelerator systems (e.g. shifting from CBS+MBT to CBS+TMTD may need antioxidant tweaks).

This ensures your tyres, belts & seals perform the same way — run after run, month after month.

🚀 How we support you at Arihant Reclamation Pvt. Ltd.

At ARPL, we supply:

✅ High-purity zinc oxide, carefully tested for lead, SSA and particle uniformity.

✅ Antioxidants like 6PPD, IPPD, & non-staining phenolics, matched to your product needs.

✅ Complete accelerator systems — CBS, MBT, MBTS, TMTD — all under one roof, so you get synergy & simplified sourcing.

Most importantly, we work alongside your technical teams to optimize recipes. Need to adjust ZnO for a summer vs winter cure profile? Wondering how to balance 6PPD with your wax system? We’re here to help — not just ship products.

👉 Ready to boost the life of your tyres, belts or molded rubber?

A few extra rupees spent on the right zinc oxide & antioxidant balance can save lakhs in field returns, downtime and warranty hassles.

Let’s ensure your compounds stay strong, flexible & crack-free — giving your customers the long service they expect.

📞 Contact Arihant Reclamation Pvt. Ltd. today to discuss your specific compound needs and get a customized solution.

| Product | Typical Use Cases |

|---|---|

| Accelerator MBT | General rubber goods, footwear soles, hoses |

| Accelerator MBTS | Tires, conveyor belts, thick molded products |

| Accelerator CBS | Fast curing for automotive rubber, mechanical goods |

| Accelerator TMTD | As ultra accelerator or sulfur donor in rubber blends |

| Accelerator ZDEC | Ultra-fast latex applications like gloves & balloons |

| Antioxidant IPPD | Protects rubber from oxygen & flex cracking |

| Antioxidant 6PPD | Outstanding ozone & weather resistance for outdoor rubber |

Contact us today to learn more about our export-grade rubber chemicals and how we can support your manufacturing needs.

Why ARPL is the Right Choice

- 🏆 Recognized Exporter & Supplier

- 🧪 ISO-certified production with strict quality control

- 🚚 Fast logistics network to all major cities in Gujarat

- 📈 Flexible MOQ & bulk order fulfillment

- 🤝 Long-term supplier to companies in SEZs and industrial parks across India

✅ Connect With Us Today!

📞 Phone: +91-8860732624

📧 Email: arihantreclamation@gmail.com

🌐 Website: www.arihantreclamationpvtltd.com