Rubber compounding and latex processing depend heavily on the selection of the correct accelerator system. Among ultra-fast accelerators, Accelerator ZDBC (Zinc Dibutyldithiocarbamate) is widely used for its high activity, rapid cure response, and excellent performance in soft rubber and latex compounds. ZDBC belongs to the dithiocarbamate family of accelerators and is known for producing fast vulcanization at relatively low temperatures.

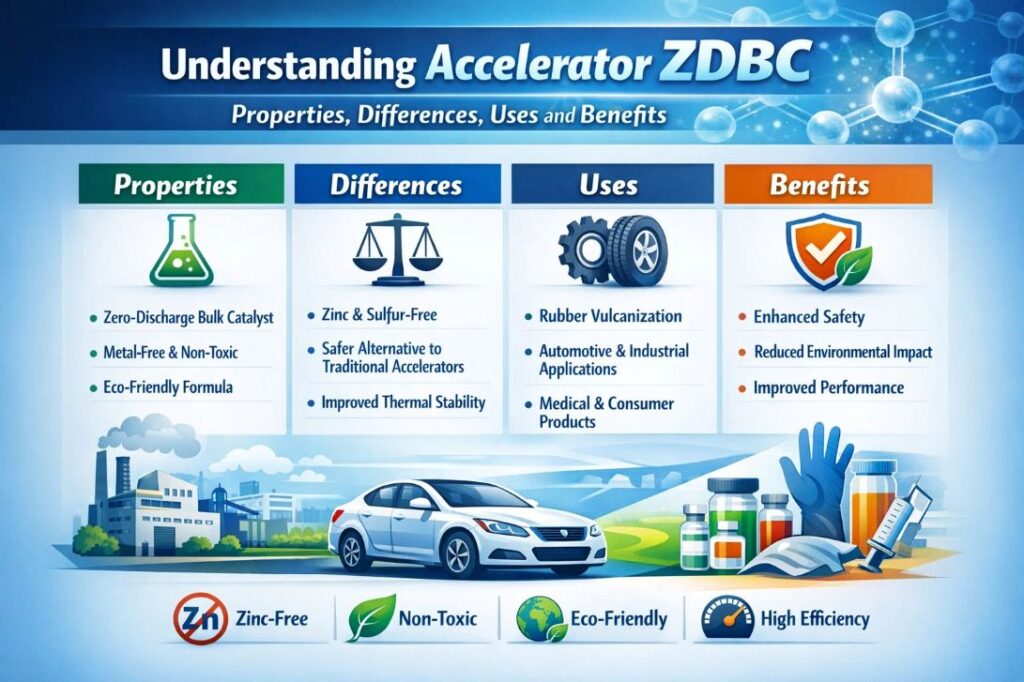

Understanding Accelerator ZDBC properties, differences, uses, and benefits helps rubber technologists, product developers, and industrial manufacturers choose the right formulation for latex goods, medical products, soft molded rubber parts, and specialty rubber applications.

What Is Accelerator ZDBC?

Accelerator ZDBC is a zinc salt of dibutyldithiocarbamic acid. It acts as an ultra-fast accelerator and is commonly used either as a primary accelerator in latex systems or as a secondary accelerator in dry rubber compounds.

ZDBC generates active sulfurating species quickly, which leads to fast crosslink formation and short cure cycles. Because of its efficiency, ZDBC is particularly suitable for products requiring rapid vulcanization and low curing temperatures.

Chemical and Physical Properties of Accelerator ZDBC

| Property | Description |

|---|---|

| Chemical Name | Zinc Dibutyldithiocarbamate |

| Chemical Family | Dithiocarbamate |

| Physical Form | Fine powder |

| Color | White to off-white |

| Odor | Mild |

| Solubility | Insoluble in water |

| Density | Approx. 1.2 g/cm³ |

| Melting Point | Around 104°C |

| Storage Stability | Good |

Role of ZDBC in Vulcanization Chemistry

Accelerator ZDBC promotes vulcanization by reacting with sulfur to form highly reactive intermediates. These intermediates quickly bond with rubber polymer chains, forming crosslinks that give rubber its elastic and mechanical properties.

Key roles of ZDBC:

- Provides very fast cure speed

- Enables low-temperature vulcanization

- Produces high crosslink density

- Improves productivity

Types of Accelerators Compared with ZDBC

| Accelerator Type | Examples | Cure Speed | Typical Use |

|---|---|---|---|

| Thiazoles | MBT, MBTS | Medium | General rubber |

| Sulfenamides | CBS, TBBS | Fast (delayed) | Tyres |

| Thiurams | TMTD | Very fast | Secondary accelerator |

| Dithiocarbamates | ZDBC, ZDEC | Ultra-fast | Latex & soft rubber |

ZDBC belongs to the fastest group of accelerators.

ZDBC vs ZDEC – Key Differences

| Parameter | ZDBC | ZDEC |

|---|---|---|

| Chemical Name | Zinc Dibutyldithiocarbamate | Zinc Diethyldithiocarbamate |

| Cure Speed | Very fast | Ultra-fast |

| Scorch Safety | Low | Low |

| Latex Compatibility | Excellent | Excellent |

| Odor | Lower | Slightly higher |

| Blooming Tendency | Low | Low |

| Preferred For | Latex & soft rubber | Latex products |

ZDBC vs TMTD – Key Differences

| Parameter | ZDBC | TMTD |

|---|---|---|

| Chemical Family | Dithiocarbamate | Thiuram |

| Nitrosamine Risk | Low | Higher |

| Cure Speed | Ultra-fast | Very fast |

| Latex Suitability | Excellent | Moderate |

| Odor | Low | Moderate |

Recommended Dosage of ZDBC

| Application | Typical Dosage (phr) |

|---|---|

| Latex goods | 0.2 – 1.0 |

| Soft rubber compounds | 0.3 – 1.2 |

| Secondary accelerator | 0.1 – 0.5 |

Higher dosages may reduce scorch safety.

Compatibility with Other Accelerators

| Accelerator | Compatibility | Remarks |

|---|---|---|

| MBT | Good | Used as secondary |

| MBTS | Good | Improves cure speed |

| CBS | Limited | Usually unnecessary |

| TBBS | Limited | Not common |

| TMTD | Low | Risk of over-cure |

| ZDEC | Poor | Redundant |

Compatibility with Rubber Types

| Rubber Type | Compatibility |

|---|---|

| Natural Rubber (NR) | Excellent |

| SBR | Good |

| BR | Good |

| NBR | Good |

| EPDM | Limited |

| IIR | Limited |

Uses of Accelerator ZDBC

Accelerator ZDBC is widely used in:

- Latex gloves

- Balloons

- Condoms

- Rubber threads

- Soft molded rubber goods

- Foam rubber

- Sponge rubber

- Rubber adhesives

Benefits of Using ZDBC

1. Very Fast Cure

Shortens vulcanization time significantly.

2. Low-Temperature Vulcanization

Suitable for heat-sensitive products.

3. Excellent Latex Compatibility

Disperses well in latex systems.

4. Good Mechanical Properties

Provides good tensile strength and elasticity.

5. High Productivity

Shorter cycle times improve output.

Limitations of ZDBC

- Low scorch safety

- Not ideal for thick rubber sections

- Must be carefully dosed

Common Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Premature curing | High ZDBC dosage | Reduce dosage |

| Poor scorch safety | Fast accelerator system | Add retarder |

| Low tensile strength | Insufficient sulfur | Adjust sulfur |

Industry Perspective

Accelerator ZDBC remains one of the most important ultra-fast accelerators for latex and soft rubber products. Its high activity, low-temperature curing capability, and compatibility with latex systems make it indispensable in many rubber manufacturing segments.

ARPL Product Support

Arihant Reclamation Pvt. Ltd. supplies high-quality ZDBC, ZDEC, MBT, MBTS, CBS, TBBS, TMTD, DPG, PVI, TMQ, TDQ and Zinc Oxide, supporting tyre and non-tyre rubber manufacturers across India.

📞 +91-8860732624

📧 arihantreclamation@gmail.com

🌐 https://arihantreclamationpvtltd.com/