Rubber aging is not just a surface-level problem — it is a chemical degradation process that directly affects mechanical strength, elasticity, resilience, and product lifespan. For tyre manufacturers, automotive rubber producers, conveyor belt manufacturers, footwear makers, and industrial rubber processors, selecting the best antioxidant for rubber aging protection is one of the most critical formulation decisions.

If the wrong antioxidant is selected, the rubber compound may pass initial quality checks but fail prematurely in the field due to cracking, hardening, brittleness, or tensile loss.

This detailed guide explains everything a rubber technologist, R&D engineer, or procurement manager must know before selecting an antioxidant.

Understanding Rubber Aging at Molecular Level

Rubber aging primarily occurs due to oxidation reactions. Natural rubber and synthetic rubbers such as SBR, NBR, BR, and EPDM contain unsaturated polymer chains. These double bonds are highly reactive and vulnerable to oxygen attack.

Step-by-Step Oxidation Mechanism

- Initiation

Heat, UV light, or mechanical stress creates free radicals in the polymer chain. - Propagation

These free radicals react with oxygen to form peroxy radicals. - Chain Reaction

Peroxy radicals attack neighboring polymer chains, creating more free radicals. - Polymer Breakdown

This leads to chain scission (breaking) or crosslink density changes. - Property Deterioration

- Loss of tensile strength

- Reduced elongation at break

- Increased hardness

- Surface cracking

Antioxidants interrupt this chain reaction by stabilizing free radicals before they damage the polymer backbone.

Why Rubber Aging Protection Is Essential in Tyre Industry

Tyres operate under:

- Continuous dynamic flexing

- High internal heat generation

- Oxygen exposure

- Ozone attack

- Road friction

Without strong antioxidant protection:

- Tread cracks appear

- Sidewall cracks form

- Heat build-up increases

- Retreadability reduces

- Safety risks increase

This is why amine-based antioxidants such as TMQ and SP Oil are widely used in tyre compounds.

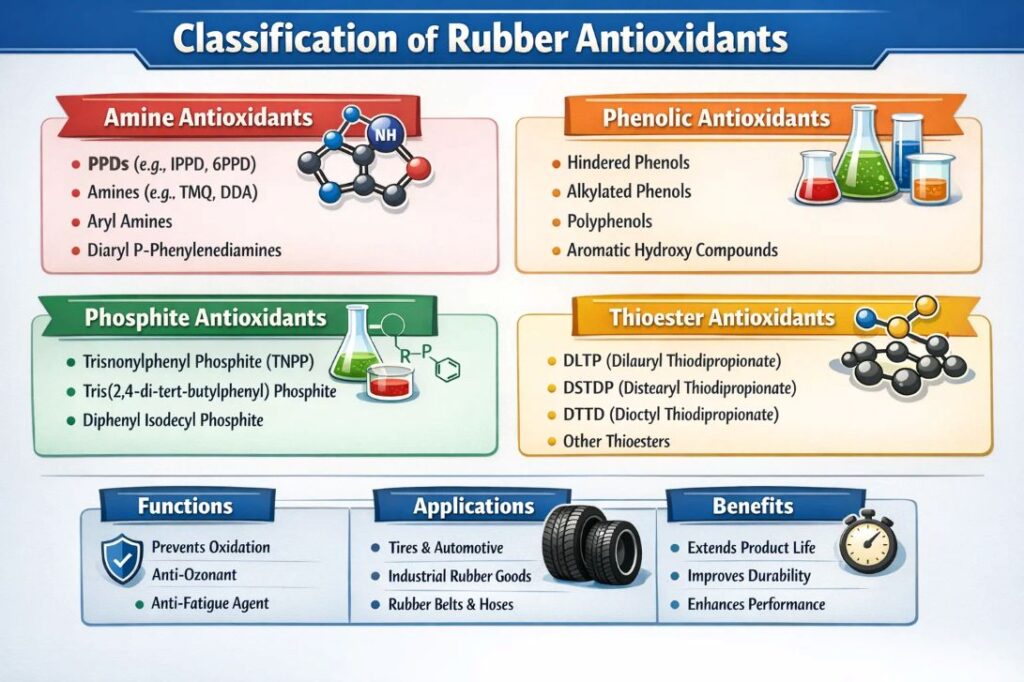

Detailed Classification of Rubber Antioxidants

1. Primary Antioxidants (Chain-Breaking Type)

These directly neutralize free radicals.

Examples:

- TMQ

- TDQ

- Antioxidant SP Oil

They donate hydrogen atoms to free radicals, converting them into stable molecules.

These are highly effective in high-temperature rubber applications.

2. Secondary Antioxidants (Preventive Type)

These decompose hydroperoxides formed during oxidation.

They are often used in combination systems for enhanced protection.

3. Antiozonants vs Antioxidants

Many rubber manufacturers confuse these.

- Antioxidants protect against oxygen and heat.

- Antiozonants protect against ozone cracking.

In many tyre formulations, both are used together for complete aging resistance.

Factors That Influence Antioxidant Selection

Selecting the best antioxidant for rubber aging protection depends on multiple technical parameters.

1. Polymer Type

Different rubbers respond differently:

- Natural Rubber (NR): Requires strong amine antioxidants.

- SBR: Needs heat-resistant protection.

- NBR: Often exposed to oil and heat.

- EPDM: More ozone resistant but still needs thermal stabilization.

2. Processing Temperature

If curing temperature exceeds 150°C, antioxidant must have high thermal stability.

3. Dynamic vs Static Application

Dynamic applications like tyres and belts need strong heat-aging resistance.

Static rubber goods may require moderate protection.

4. Color Requirement

Amine antioxidants may cause staining.

Phenolic antioxidants are preferred in light-colored compounds.

In-Depth Comparison: TMQ, TDQ and SP Oil

TMQ (Polymerized Quinoline Type)

TMQ is one of the most widely used antioxidants in tyre industry.

Key Features:

- Excellent heat aging resistance

- Strong oxidation inhibition

- Good permanence in rubber

- Cost-effective in bulk production

Ideal For:

- Tyre tread compounds

- Sidewall compounds

- Conveyor belts

- Heavy-duty rubber products

TDQ

TDQ offers similar protection but differs in molecular structure and dispersion behavior.

Key Advantages:

- Good heat resistance

- Effective oxidation control

- Suitable for general rubber goods

Often used where moderate-to-high heat protection is required.

Antioxidant SP Oil

SP Oil provides:

- Good dispersion in rubber matrix

- Strong processing compatibility

- Balanced cost-performance ratio

- Effective aging control in tyre and non-tyre rubber

It is often used in combination systems to enhance overall antioxidant efficiency.

Synergistic Effect: Why Combination Systems Work Better

In modern rubber compounding, manufacturers rarely rely on a single antioxidant.

A combination such as:

TMQ + SP Oil

can provide:

- Extended thermal protection

- Improved dispersion

- Better long-term aging stability

- Reduced volatility loss

This synergy increases compound life and improves mechanical retention after aging tests.

Laboratory Testing for Aging Protection

To determine the best antioxidant, manufacturers perform:

1. Oven Aging Test

Rubber samples aged at 70–100°C for 24–168 hours.

Measured parameters:

- Tensile retention %

- Elongation retention %

- Hardness change

2. Heat Build-Up Test

Measures internal heat generation during dynamic stress.

3. Accelerated Aging Test

Simulates long-term environmental exposure.

4. Ozone Resistance Test

Evaluates crack formation under ozone concentration.

High-quality antioxidants significantly improve retention values.

Impact on Mechanical Properties

A good antioxidant system ensures:

- Higher tensile strength retention

- Better elongation retention

- Reduced compression set

- Stable hardness over time

- Lower crack growth rate

This directly impacts product warranty and customer satisfaction.

Economic Benefits of Using the Right Antioxidant

Many manufacturers focus only on raw material cost.

However, the real cost includes:

- Product failure rate

- Warranty claims

- Brand damage

- Reduced product lifespan

- Frequent replacement cycles

Investing in high-quality antioxidants reduces long-term financial risk.

Cost-effective antioxidants like SP Oil offer a balanced solution between performance and pricing.

Storage and Handling Guidelines

To maintain antioxidant performance:

- Store in cool, dry conditions

- Avoid direct sunlight

- Prevent moisture exposure

- Use airtight packaging

Proper storage ensures chemical stability and shelf life.

Common Mistakes in Antioxidant Selection

- Choosing only based on price

- Ignoring compatibility with accelerators

- Overloading dosage without testing

- Not performing aging tests

- Using phenolic antioxidants in high-heat applications

Correct technical evaluation is essential.

Why Arihant Reclamation Pvt. Ltd. Is a Trusted Supplier

Arihant Reclamation Pvt. Ltd. supplies high-quality:

- TMQ

- TDQ

- Antioxidant SP Oil

along with a complete range of rubber accelerators including:

ZDBC, ZDEC, MBT, MBTS, CBS, TBBS, TMTD, DPG, PVI and Zinc Oxide.

Our antioxidants are widely used by tyre and non-tyre rubber manufacturers across India because of:

- Consistent industrial-grade quality

- Reliable bulk supply

- Technical-grade purity

- Competitive pricing

- Timely dispatch

We understand that rubber aging protection directly affects product durability and market reputation. That is why we focus on supplying dependable chemical solutions for industrial rubber compounding.

The best antioxidant for rubber aging protection depends on:

- Application type

- Heat exposure level

- Polymer system

- Cost-performance requirement

For high-heat, dynamic rubber products, amine-based antioxidants such as TMQ and SP Oil provide superior aging resistance.

Combination systems often offer the most effective long-term protection.

By selecting the right antioxidant system, manufacturers can:

- Extend rubber product lifespan

- Improve mechanical stability

- Reduce cracking and degradation

- Enhance brand reliability

For high-quality antioxidant solutions and rubber chemicals, manufacturers across India rely on Arihant Reclamation Pvt. Ltd.

📞 ARPL Product Support

Arihant Reclamation Pvt. Ltd.

📞 +91-8860732624

📧 arihantreclamation@gmail.com

🌐 https://arihantreclamationpvtltd.com/

Supporting tyre and non-tyre rubber manufacturers with reliable rubber chemical solutions across India.

ARPL_Brochure