Rubber chemicals play a critical role in the performance and durability of finished rubber products. Among these, DPG Rubber Accelerator (Diphenyl Guanidine) is widely recognized for its importance in rubber compounding. From tyres to industrial rubber goods, DPG accelerator works behind the scenes to ensure faster vulcanization, better elasticity, and long-lasting strength.

This blog explores the role of DPG in rubber compounding, the benefits it offers to manufacturers worldwide, and viable alternatives that meet the needs of different markets such as the USA, Germany, India, China, Brazil, and beyond.

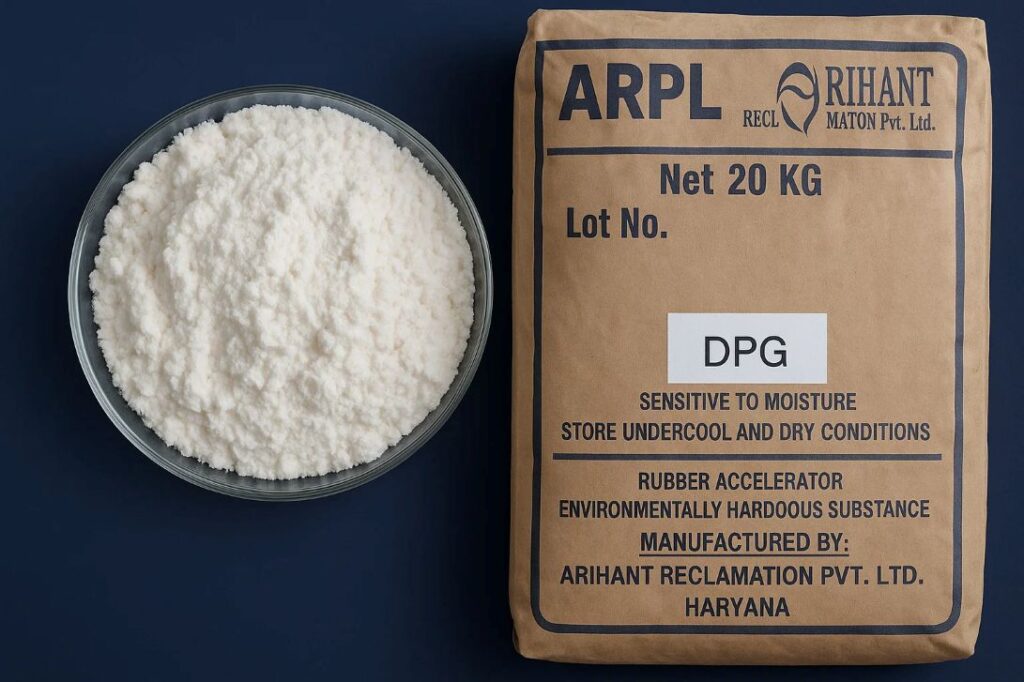

What is DPG Rubber Accelerator?

DPG is a secondary accelerator used in the vulcanization of natural and synthetic rubbers. Unlike primary accelerators, DPG functions best in combination with other accelerators such as MBT or CBS. Its presence ensures:

- Stable curing process without scorching.

- Improved mechanical properties of rubber.

- Extended product lifespan, especially in tyres, belts, and footwear.

Benefits of DPG in Rubber Compounding

Manufacturers prefer DPG accelerator due to its versatile performance in rubber chemicals. Below are some of the key benefits:

| Benefit | Explanation | Application Area | Why It Matters |

|---|---|---|---|

| Faster Vulcanization | Speeds up the curing process when combined with other accelerators | Tyre industry, conveyor belts | Saves energy and reduces production time |

| Heat Resistance | Provides improved thermal stability | Automotive parts, hoses | Enhances safety and durability |

| Compatibility | Works well with MBT, MBTS, CBS, and TBBS | Rubber compounding labs | Flexibility in formulations |

| Cost Efficiency | Reduces wastage by ensuring controlled curing | General rubber goods | Improves profit margins for manufacturers |

Role of DPG in Rubber Chemicals Across Industries

The demand for rubber accelerators and rubber antioxidants varies across different countries based on climate, industry, and product demand. Here’s how DPG plays a role worldwide:

| Region | Primary Use of DPG | Key Rubber Chemicals Paired | Industrial Focus |

|---|---|---|---|

| India | Tyres, footwear, and general rubber goods | MBT, CBS, Zinc Oxide | Automotive growth & exports |

| USA | High-performance tyres and industrial seals | TBBS, Antioxidants (6PPD, TMQ) | Advanced automotive & aerospace |

| Germany | Conveyor belts, rubber seals, specialty products | CBS, MBTS | Engineering and heavy industry |

| China | Mass tyre production, rubber footwear | MBT, DPG, ZDBC | Large-scale manufacturing |

| Brazil | Agricultural tyres and rubber mats | CBS, Antioxidants | Farming & logistics needs |

Alternatives to DPG Accelerator

While DPG has its strengths, some industries prefer alternatives depending on product requirements or environmental regulations.

| Alternative Accelerator | Performance Level | Typical Use | Key Advantage |

|---|---|---|---|

| MBT (Mercaptobenzothiazole) | Primary accelerator | General compounding | Reliable and widely available |

| CBS (N-Cyclohexyl-2-benzothiazole sulfenamide) | Delayed action accelerator | Tyres, heavy rubber goods | Safe processing window |

| TBBS (N-tert-butyl-2-benzothiazole sulfenamide) | High efficiency | High-performance tyres | Excellent balance of speed and control |

| ZDBC (Zinc dibutyl dithiocarbamate) | Ultra accelerator | Latex goods, gloves | Best for fast vulcanization |

Challenges in Using DPG Rubber Accelerator

Although widely used, manufacturers should also consider:

- Health and safety regulations in Europe and the USA.

- Potential replacement demand in eco-friendly compounds.

- Price fluctuations depending on raw material availability in Asia.

This is why many companies explore both DPG and its alternatives when designing formulations for export markets.

Conclusion

DPG Rubber Accelerator continues to be a cornerstone in rubber chemicals and compounding, delivering reliable performance in tyres, belts, and general rubber products. Its ability to work with MBT, CBS, and other accelerators makes it indispensable for manufacturers across India, USA, China, Germany, Brazil, and other global markets.

However, with rising focus on eco-friendly solutions and regulatory changes, businesses must also stay informed about alternatives like TBBS, CBS, and ZDBC to maintain quality and compliance.

👉 If you are looking for a trusted manufacturer and supplier of rubber accelerators, antioxidants, and rubber chemicals in India, we can help.

| Product | Typical Use Cases |

|---|---|

| Accelerator MBT | General rubber goods, footwear soles, hoses |

| Accelerator MBTS | Tires, conveyor belts, thick molded products |

| Accelerator CBS | Fast curing for automotive rubber, mechanical goods |

| Accelerator TMTD | As ultra accelerator or sulfur donor in rubber blends |

| Accelerator ZDEC | Ultra-fast latex applications like gloves & balloons |

| Antioxidant IPPD | Protects rubber from oxygen & flex cracking |

| Antioxidant 6PPD | Outstanding ozone & weather resistance for outdoor rubber |

Why ARPL is the Right Choice

- 🏆 Recognized Exporter & Supplier

- 🧪 ISO-certified production with strict quality control

- 🚚 Fast logistics network to all major cities

- 📈 Flexible MOQ & bulk order fulfillment

- 🤝 Long-term supplier to companies in SEZs and industrial parks across India

✅ Connect With Us Today!

📞 Phone: +91-8860732624

📧 Email: arihantreclamation@gmail.com

🌐 Website: www.arihantreclamationpvtltd.com