Vulcanization is the process that transforms natural rubber into a durable, elastic material used in tyres, seals, conveyor belts, and countless other rubber products. At the heart of this transformation are rubber accelerators —specialized chemicals that significantly speed up the vulcanization reaction, improve processing efficiency, and enhance the physical properties of finished rubber goods.

In this guide, we present a complete list of rubber accelerators, their categories, uses, and how each one contributes to industrial rubber manufacturing—especially in India’s growing rubber industry.

📘 What Are Rubber Accelerators?

Rubber accelerators are chemical compounds added to rubber compounds to speed up the vulcanization process. Without accelerators, sulphur vulcanization would take hours at high temperatures—making the process economically unviable.

Accelerators reduce vulcanization time, improve scorch safety, and provide enhanced mechanical properties like:

- Tensile strength

- Elasticity

- Abrasion resistance

- Heat and chemical resistance

🧪 Types of Rubber Accelerators (With Chemical Names)

Rubber accelerators are broadly classified into Primary Accelerators and Secondary Accelerators (Ultra/Delayed Action).

| Accelerator Code | Chemical Name | Type | Vulcanization Speed | Applications |

|---|---|---|---|---|

| MBT | Mercaptobenzothiazole | Primary | Medium | General-purpose, tyres, footwear |

| MBTS | Dibenzothiazyl disulfide | Primary | Slower than MBT | Conveyor belts, seals, hoses |

| CBS | N-Cyclohexyl-2-benzothiazole sulfenamide | Delayed | Fast cure after scorch delay | Tyres, molded goods |

| TMTD | Tetramethylthiuram disulfide | Ultra | Very fast | Latex, adhesives, fast-cure items |

| ZDEC | Zinc diethyl dithiocarbamate | Ultra | Very fast | Latex goods, balloons |

| ZDBC | Zinc dibutyl dithiocarbamate | Ultra | Very fast | Latex, light-colored products |

| DPG | Diphenyl guanidine | Secondary | Booster | Combined with MBT or MBTS |

| PVI | N-(Cyclohexylthio) phthalimide | Pre-vulcanization Inhibitor | – | Controls scorch time in high-temp processes |

| ZMBT | Zinc 2-mercaptobenzothiazole | Ultra | Medium-Fast | Transparent/colored rubber items |

| 6PPD | N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine | Antioxidant | – | Tyres, industrial rubber (anti-aging) |

| TMQ | Polymerized 2,2,4-trimethyl-1,2-dihydroquinoline | Antioxidant | – | Heat-resistance, long-life rubber products |

🏭 Which Rubber Accelerators Are Used in India?

India’s tyre and rubber goods industry heavily relies on the following:

- CBS and MBTS – Most popular for tyre manufacturing

- TMTD – For high-speed vulcanization in latex and cable insulation

- MBT and DPG – For technical rubber products

- 6PPD and TMQ – To resist ozone, oxidation, and heat aging

🏆 Benefits of Using the Right Rubber Accelerator

Choosing the right accelerator impacts:

- Production Efficiency – Faster curing saves energy & time

- Product Life – Better resistance to wear, heat, aging

- Cost Reduction – Lower cure time means reduced energy costs

- Environmental Safety – Proper accelerators minimize toxic emissions during processing

📦 Common Applications of Rubber Accelerators

| Product | Accelerator Used | Function |

|---|---|---|

| Tyres | CBS, 6PPD, TMQ | Delayed cure, anti-aging |

| Conveyor Belts | MBTS, DPG | Medium-fast curing |

| Rubber Hoses | MBT, CBS | Strength and flexibility |

| Latex Gloves | ZDEC, ZDBC | Fast curing, non-staining |

| Rubber Seals | MBT, MBTS | Heat and chemical resistance |

| Footwear Soles | MBT, ZMBT | Durable, abrasion-resistant |

🧾 Rubber Accelerator Selection Chart

Here’s a simplified view to help manufacturers pick the right accelerator:

| Need | Recommended Accelerator |

|---|---|

| Fast Vulcanization | TMTD, ZDEC |

| Delayed Action / Safe Processing | CBS |

| Low Temperature Curing | ZDBC |

| Improved Aging Resistance | 6PPD, TMQ |

| Transparent Products | ZMBT |

🇮🇳 Why Indian Manufacturers Should Care

India is one of the top rubber-consuming nations, and quality accelerators are critical for meeting international standards in tyres, industrial rubber goods, footwear, and automotive components.

As sustainability and performance demands grow, the right blend of accelerators will define product success, compliance, and global acceptance.

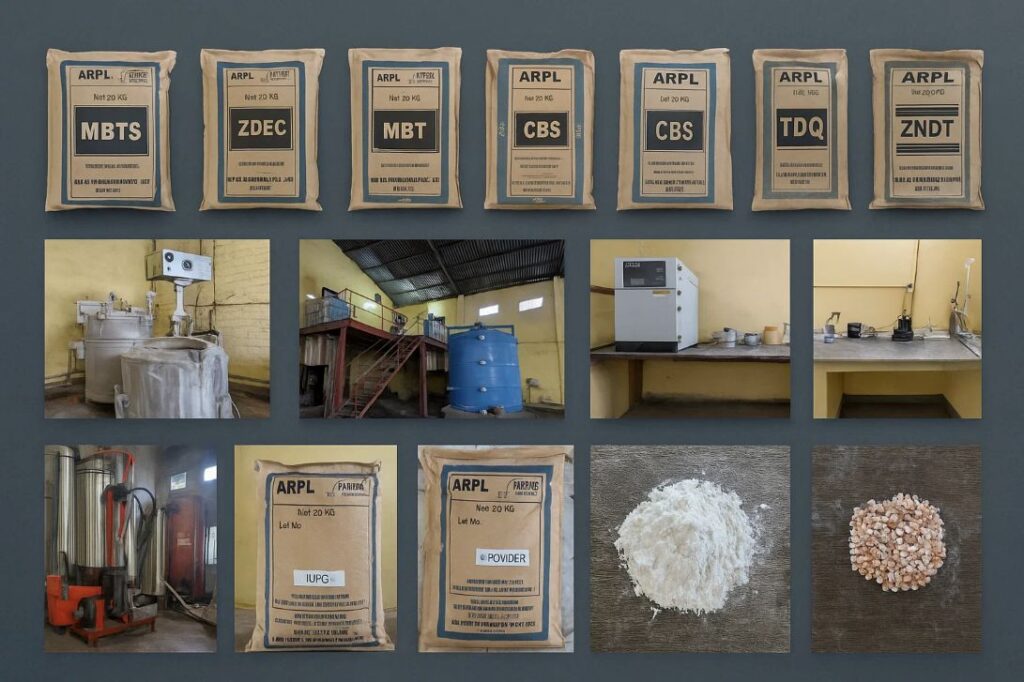

✅ Why Choose ARPL as Your Rubber Accelerator Supplier

At Arihant Reclamation Pvt. Ltd. (ARPL), we are a leading manufacturer and exporter of high-quality rubber accelerators in India. With ISO-certified processes, bulk supply capabilities, and technical expertise, we offer:

- A full range of accelerators: MBT, MBTS, CBS, TMTD, ZDEC, ZDBC, PVI, DPG, ZMBT, and more

- Consistent product quality for critical vulcanization applications

- Custom packaging and global shipping support

- Ideal for tyre, footwear, conveyor, seal, and industrial rubber product manufacturers

📞 Need Rubber Accelerators in Bulk?

Get in touch with ARPL – your trusted Indian partner for industrial-grade rubber chemicals. We are committed to quality, compliance, and customer satisfaction.

✅ Connect With Us Today!

📞 Phone: +91-8860732624

📧 Email: arihantreclamation@gmail.com

🌐 Website: www.arihantreclamationpvtltd.com

❓ Frequently Asked Questions (FAQs)

Q1. What is a rubber accelerator and why is it important?

A: A rubber accelerator is a chemical additive that speeds up the vulcanization (curing) process of rubber with sulfur. It improves processing time, enhances the durability and elasticity of rubber products, and helps manufacturers achieve optimal performance in tyres, seals, belts, and more.

Q2. Which rubber accelerators are most commonly used in India?

A: In India, the most widely used accelerators include MBT, MBTS, CBS, TMTD, and ZDEC, particularly in tyre and industrial rubber manufacturing sectors. CBS is especially popular due to its delayed action and excellent scorch safety.

Q3. What is the difference between primary and secondary accelerators?

A:

- Primary accelerators (like MBT, MBTS, CBS) initiate and carry the bulk of vulcanization.

- Secondary accelerators (like DPG, TMTD, ZDEC) are used to boost the effect, improve cure rate, and adjust vulcanization properties.

Q4. Which accelerators are suitable for latex products?

A: For latex-based products such as gloves, balloons, and adhesives, ZDEC, ZDBC, and TMTD are ideal due to their ultra-fast vulcanization and low toxicity at low dosages.

Q5. What does PVI do in rubber compounding?

A: PVI (Pre-Vulcanization Inhibitor) is used to control premature vulcanization (scorching) during processing. It improves safety during high-temperature mixing and extends the processing window.

Q6. How do I choose the right rubber accelerator for my application?

A: Consider the following factors:

- Desired cure speed

- Processing temperature

- Product color (non-staining vs. staining)

- Aging/heat resistance requirements

- Application (tyres, latex, hoses, footwear, etc.)

You can refer to the Rubber Accelerator Selection Table above or consult with a supplier like ARPL for guidance.

Q7. Are rubber accelerators hazardous to health?

A: Some accelerators, especially thiurams and dithiocarbamates, may cause skin irritation or allergic reactions. Proper handling, PPE usage, and compliance with MSDS guidelines are important. ARPL provides detailed safety data sheets with every shipment.

Q8. Can I use multiple accelerators together?

A: Yes. In fact, many formulations use a combination of primary and secondary accelerators to fine-tune curing speed, safety, and mechanical properties. For example, MBTS is often combined with DPG, and CBS can be combined with TMTD for faster curing.

Q9. What is the shelf life of rubber accelerators?

A: Most rubber accelerators have a shelf life of 12 to 24 months if stored properly in a dry, cool environment away from direct sunlight and moisture. Packaging must remain sealed until use.

Q10. Does ARPL offer customized packaging or bulk delivery options?

A: Absolutely. ARPL provides customized packaging solutions, including bags, drums, and palletized shipments. We also offer bulk orders and global delivery with full compliance to industry standards.